Six Sigma and the Delicious Dominance of Domino’s Pizza

Pizza and process improvement might not seem like the most obvious pairing, but just as extra cheese and pepperoni create a mouthwatering combo, Six Sigma and Domino’s Pizza joined forces to cook up some impressive results. Let’s slice into this tasty tale of operational efficiency.

Domino’s Topples: The Fall Before the Rise

At the turn of the millennium, Domino’s found itself in a crusty situation. Despite being one of the world’s leading pizza chains, Domino’s was dropping the ball (or should we say, the pizza) on product quality and delivery times. Poor reviews peppered their reputation, and it was clear something needed to change.

Inviting Six Sigma to the Pizza Party

Like a beacon of hope for a better, more efficient future, Six Sigma arrived on the scene. A methodology aimed at reducing errors and enhancing processes, Six Sigma’s goal was to whittle defects down to a minuscule 3.4 per million opportunities. In pizza terms, imagine making nearly 300,000 pizzas and finding only one olive out of place. Now that’s precision!

Domino’s – The Transformation

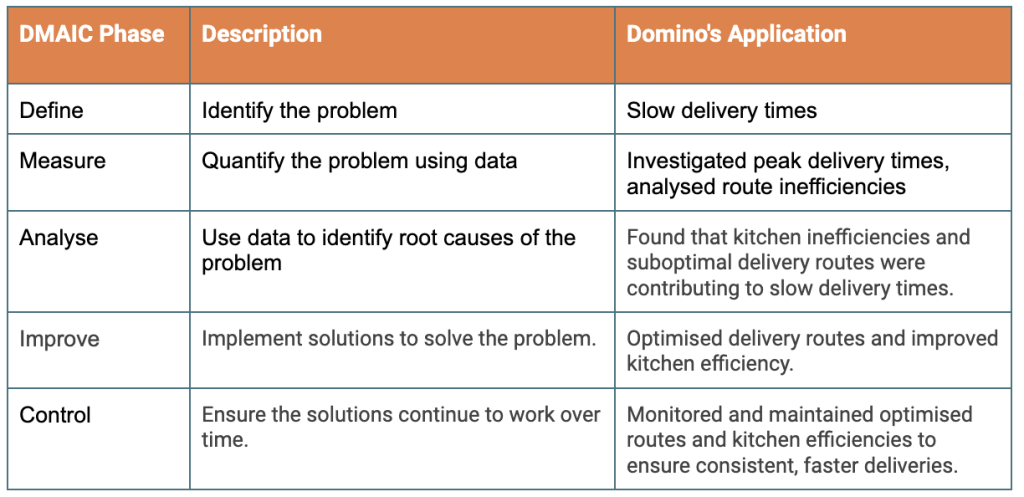

Thanks to the application of Six Sigma, Domino’s revolutionised its operational processes. Through rigorous data analysis, the pizza giant identified bottlenecks and inefficiencies in their pizza-making and delivery operations. Using Six Sigma’s DMAIC framework (Define, Measure, Analyse, Improve, Control), they meticulously measured and improved each process.

For instance, let’s look at Domino’s pizza delivery times. They defined the problem (slow delivery times), measured and analysed data (investigated peak times, route inefficiencies, etc.), improved the process (optimised routes, improved kitchen efficiencies), and controlled the new process (maintained and monitored the improvements). The result? Faster deliveries, hotter pizzas, happier customers, and an impressive boost in their bottom line.

Six Sigma: The Perfect Recipe for Success

By 2021, Domino’s had risen like the perfect pizza dough, claiming the title of the world’s largest pizza seller by sales. The Six Sigma strategies helped Domino’s reinvent its brand, regain customer trust, and redefine the pizza delivery industry.

When they invited Six Sigma to their pizza party, they didn’t just sprinkle it like an extra topping. Instead, they kneaded it into the very dough of their operations. The secret sauce was in the data – collected, analysed, and utilised to pinpoint process inefficiencies and serve up solutions.

How did they do it you ask, here’s a breakdown:

Delivery Route Optimisation

One of the critical areas Domino’s focused on was its delivery process. Six Sigma’s data-driven approach revealed a significant cause of delayed deliveries: inefficient routes. The solution? Domino’s optimised these routes using a mix of advanced GPS technology and data analysis. Drivers could now find the fastest paths to their destinations, reducing delivery times and ensuring that the pizza reached the customers piping hot.

Revamping the Kitchen Operations

Domino’s also turned a keen eye to their kitchen operations. Every process was measured and analyzed for inefficiency, from order placement to pizza baking. As a result, Domino’s discovered that its traditional pizza-making process could be streamlined. They introduced a ‘Just-in-Time’ cooking model where the pizza’s preparation aligned more accurately with the delivery schedule. This improved kitchen efficiency while ensuring that every pizza was as fresh as possible upon delivery.

Embracing Technology for Order Efficiency

Technology played a crucial role in Domino’s Six Sigma-driven transformation. Domino’s launched a new ordering system that reduced errors and increased speed. Their highly successful app streamlined the ordering process and incorporated a real-time pizza tracker. This allowed customers to know the status of their orders at any given moment, increasing transparency and customer satisfaction.

By implementing these changes, Domino’s significantly reduced their defect rate, improved customer satisfaction, and increased their market share – proof that with Six Sigma, even the sky (or should we say, the pizza crust) isn’t the limit!

Take a Slice from Domino’s Book

Six Sigma is no secret ingredient. Its success at Domino’s is a testament to its versatility and efficiency-boosting power across industries. Whether you’re a pizza powerhouse, a healthcare hub, or a tech titan, Six Sigma’s disciplined, data-driven approach can add value to your operations.

Crispy Conclusion: Serving Up Quality with Six Sigma

Domino’s remarkable transformation through Six Sigma proves that operational excellence isn’t just for manufacturing or tech giants. Any business, from fast food to fintech, can benefit from Six Sigma’s meticulous methodologies.

So, as we sign off from this delicious discourse on Six Sigma, remember – much like a perfectly baked pizza, operational excellence is a balanced blend of the right ingredients and processes. With Six Sigma in your toolkit, your business, too, can rise to the top!